WARM precision air conditioner for the Hard X-ray Free Electron Laser Facility project at Shanghai Tech University

Basic situation of customers:

Hard X-ray Free-Electron Laser Facility – A core vehicle of China's National Science and Technology System

Hard X-ray Free-Electron Laser Facility – A Pillar of China's National Science and Technology Strategy

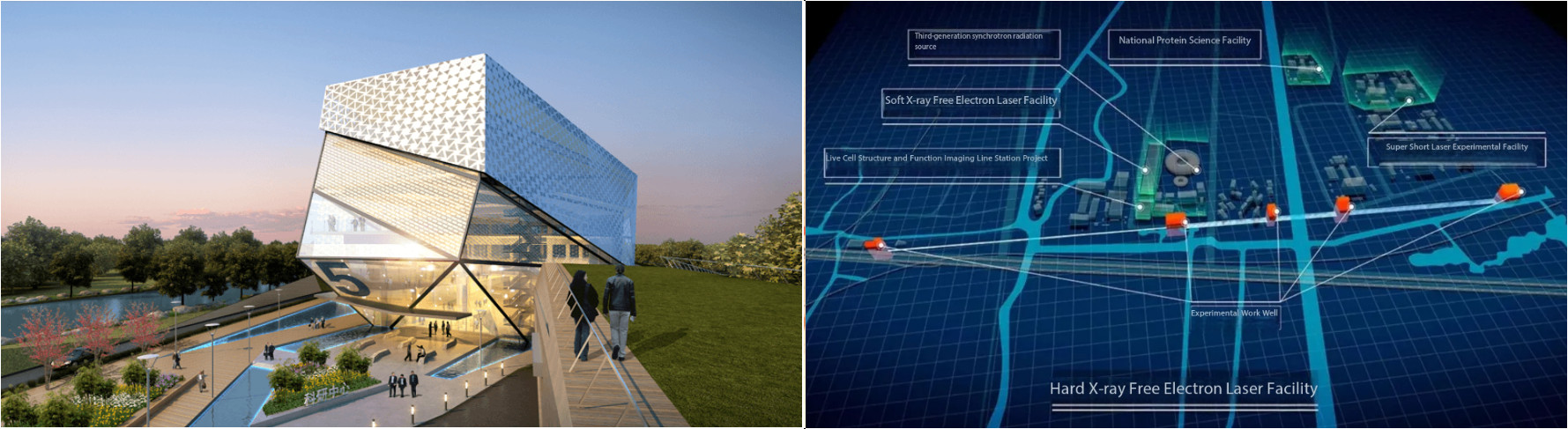

The Hard X-ray Free-Electron Laser Facility (XFEL) represents a major scientific infrastructure project prioritised during China's 13th Five-Year Plan period, aiming to establish a globally leading photon science research centre. Located in Zhangjiang Science City, Pudong, Shanghai, the completed facility will form a cluster effect with the Shanghai Synchrotron Radiation Facility and the Shanghai Soft X-ray Free-Electron Laser Facility. This will propel China into a tripartite leadership position in photon science alongside the United States and Europe. Its core equipment, including superconducting accelerator modules and precision shielding panels, imposes stringent environmental control requirements: maintaining temperature fluctuations within ±0.1°C, achieving million-class cleanliness, and ensuring low vibration levels within the narrow and elongated tunnel. These conditions are essential for the stable operation of superconducting modules and the high coherence of X-ray beams.

Issues that need resolving:

Precision control challenges in extreme environments

1. Environmental Sensitivity of Superconducting Modules

Each 1.3GHz superconducting acceleration module measures 12.2 metres in length and weighs 8.5 tonnes, comprising 18,000 precision components. It exhibits extreme sensitivity to temperature fluctuations. Deviations exceeding ±1°C may cause loss of superconducting state, requiring year-round constant temperature control.

2. Air Cleanliness Assurance: Dust concentration within the tunnel must be maintained at ISO Class 5 (fewer than 3,520 particles per cubic metre measuring 0.1 micrometres) over extended periods. Conventional filtration systems are prone to efficiency degradation due to condensation.

3. Vibration Isolation and Energy Efficiency: Microscopic vibrations generated during equipment operation must be controlled at the micrometre level, while reducing air conditioning system energy consumption to meet green science standards.

4. Remote Monitoring and Fault Prediction: With equipment dispersed throughout the tunnel, multi-unit coordinated control and real-time fault diagnosis are required to minimize manual inspection frequency.

Solution:

Customised Innovation for the MWV-AJ45U Precision Air Conditioner

WARM Refrigeration, drawing upon over two decades of expertise in modular air-cooled technology, has developed the MWV-AJ45U precision air conditioner specifically for this project, which integrates four core technologies:

1. Dual-stage compression with heat recovery technology

Employing high-efficiency scroll hermetic compressors alongside R22 environmentally friendly refrigerant, it achieves stable operation across a broad temperature range from -10°C to 48°C. The heat recovery module converts waste heat into 65°C hot water for preheating tunnel equipment, elevating the integrated energy efficiency ratio (EER) to 3.8 – delivering 40% greater energy savings than conventional solutions.

2. Micro-channel Heat Exchange and Intelligent Air Distribution System

The unit incorporates micro-channel parallel-flow heat exchangers, boosting heat transfer efficiency by 25%. Combined with CFD simulation-optimized air ducts, this creates a uniform airflow field within the tunnel. Inverter fans enable 0-100% stepless speed regulation, controlling airflow deviation within ±3% to eliminate temperature and humidity dead zones.

3. Low-Vibration Design and Multi-Layer Damping

A suspended type compressor mounting structure, integrated with rubber isolation pads and spring dampers, reduces the unit's vibration to below 3μm/s². By dynamic balancing correction technology it ensures fan rotor dynamic balance precision at G0.4 grade, preventing vibration transmission to superconducting modules.

4. Modularity and Rapid Deployment Capability

The unit employs standardised modular design, with each unit delivering 45kW cooling capacity,which is scalable to over 200kW through parallel connection. Supporting factory prefabrication and on-site assembly, installation cycles are reduced by 60%, accommodating to projects tight in schedules.

Customer benefits:

The dual realisation of technology-driven empowerment and sustainable Value

1. Ensuring stable operation of critical national infrastructure

Following the deployment of precision air conditioners, temperature fluctuations within the tunnel are maintained within ±1°C, with humidity stabilised at 45% ±5%. This has reduced the failure rate of superconducting modules during continuous operation by 90%, providing essential environmental support for stable X-ray beam output.

2. Reduced life-cycle costs:

Energy efficiency optimisation reduced annual electricity consumption per unit by 120,000 kWh. Calculated at Shanghai's industrial electricity rates, this yields annual savings of approximately ¥96,000.

Modular design enables capacity expansion on demand, avoiding initial over-investment and reducing project start-up costs by 25%.

3. Demonstrating Benchmark Effect:

This project stands as a flagship case for WARM Refrigeration within scientific research field. Subsequent engagements include constant temperature and humidity units for CNNC Operations & Maintenance offices and fresh air air conditioning systems for Shanghai Rural Commercial Bank's Zhangjiang Data Centre, establishing a technology reuse effect.